Safety testing requirements

·Contact with various patient samples, the operator is at risk of contact with infection

Check efficiency requirements

·At present, manual labor is tired of repeated operation actions, and personnel cannot carry out other more urgently needed inspection tasks.

Inspection quality requirements

·In the process of sample inoculation and scribing, a little bit of staff strength will scratch the culture medium in the culture dish, and the accuracy of the analysis data will cause deviation

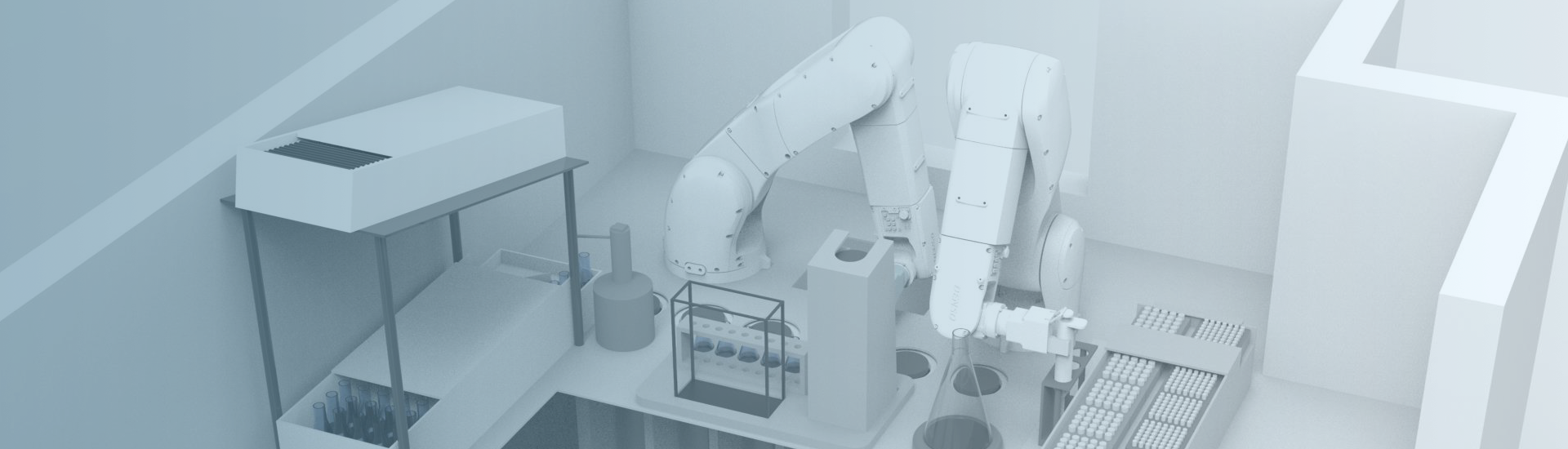

·The system solution maximizes the complex operations of laboratory technicians, greatly improves the degree of automation in the microbiology laboratory to achieve sample inoculation and streaking on the petri dish to achieve uniform and complete coverage of the sample

·Provides a hygienic and safe solution to eliminate the risk of sample infection and operator infection

·Ensure repeatable and accurate sample processing, high-quality diagnosis and full traceability

High throughput platform: 80 pcs/hour

·Standardized inoculation process: significantly improve the isolation rate of a single colony, standardize the operation, improve the success rate of the experiment, and improve and guarantee the work efficiency

·No cross-contamination, less contact with infectious specimens, higher biological safety

·Reduce repetitive work and quantitative inoculation of specimens to achieve colony count

·Small operating space, intelligent system, easy operation, accept user-defined mode