Inspection quality requirements

·The current manual fatigue operation is prone to secondary pollution and the quality of inspection is unstable

Calibration efficiency requirements

At present, all manual inspections, the operator is at risk of contact

Inspection quality requirements

·In the peak detection period, the number of personnel needs to increase, and the detection operation cannot be carried out for a long period of time

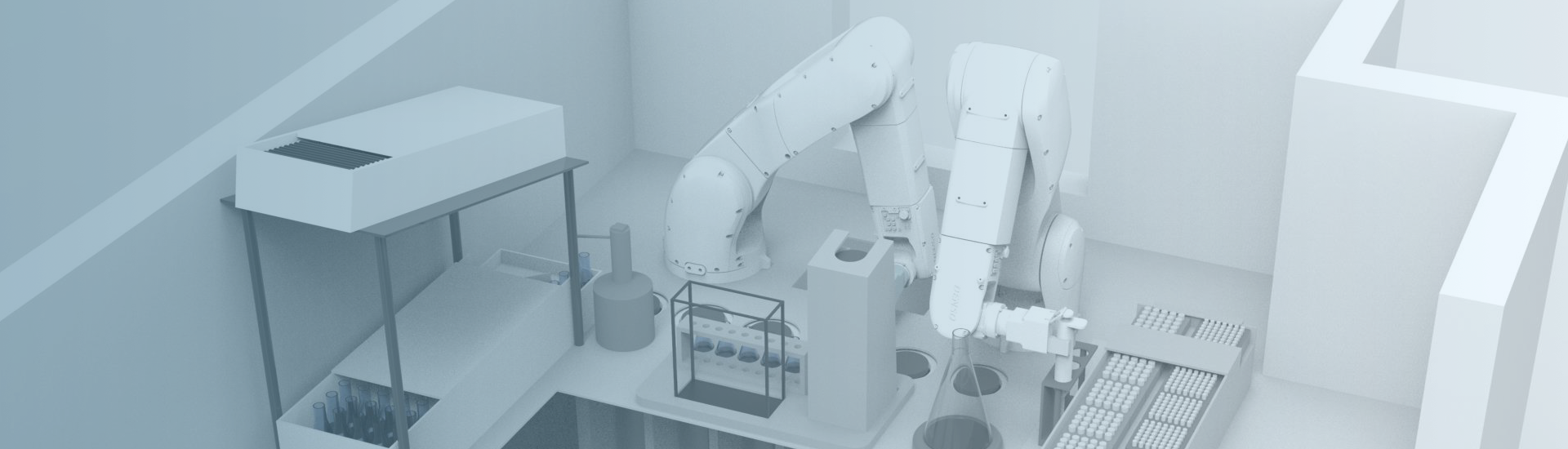

·Realize laboratory testing solutions through intelligent collaborative robots, and achieve full-process inspection operations in full compliance with the requirements of the GB4789 standard.

·Accurately grasp by the robot, high-precision quantitative operation, high-quality and stable detection of 0.01ml error is achieved

·Realize the fully automatic sample processing operation through the robot solution. If any object breaks into the test area, the machine can be stopped immediately to protect the operator in real time

·The program has high operational flexibility and can perform dexterous movements in a complex space environment

·Customized design to better complete the general operation of a variety of experimental equipment

·Simple human-computer interaction interface, flexible selection of sample processing methods to meet the different needs of users

·24 hours of continuous detection tasks, high throughput processing capacity of 100 samples in 4 hours